When people think about submarines, they often picture the hull, the torpedoes, or the periscope. But the real game-changer sits deep inside—the Nuclear Submarine Reactor. This compact powerhouse gives modern submarines something conventional diesel-electric boats simply cannot match: the ability to stay submerged for months at a time, cruise at high speeds, and run every system onboard without ever surfacing for air or fuel.

It all started back in 1954 when the USS Nautilus proved that nuclear propulsion could work underwater. That single breakthrough rewrote the rules of naval warfare. Suddenly, submarines weren’t tied to snorkeling schedules or battery charge limits. They became true underwater vessels capable of global reach, sustained operations, and unmatched stealth. Today, nuclear reactors don’t just power submarines—they define what a modern submarine can do and where it can go.

(see the generated image above)

What Is a Nuclear Submarine Reactor?

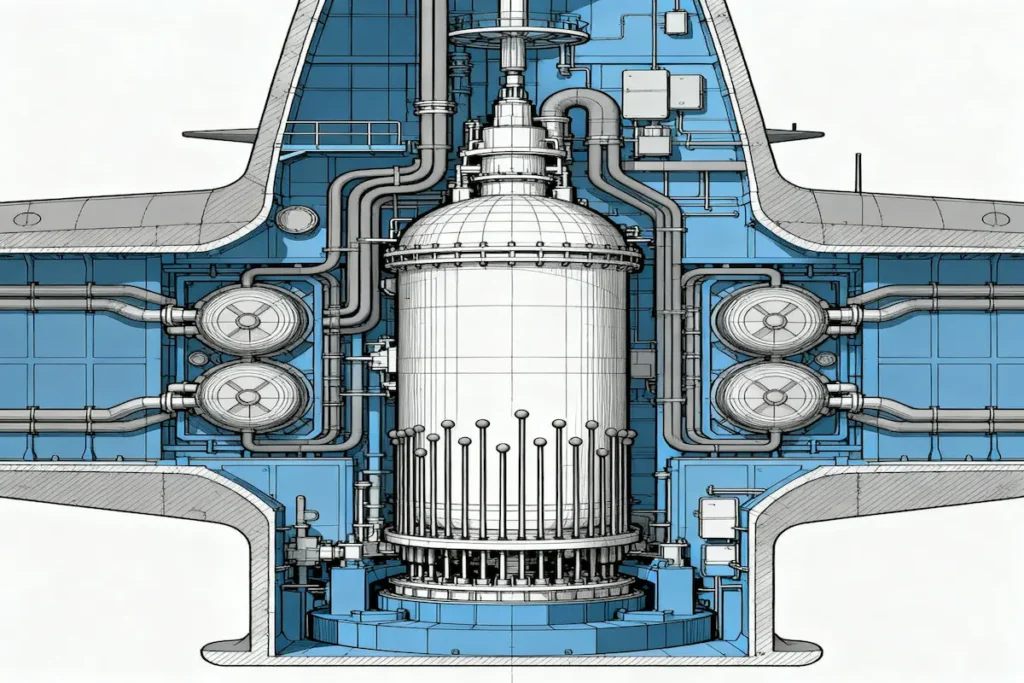

A Nuclear Submarine Reactor is basically a specialized pressurized water reactor crammed into a submarine’s hull. But calling it “specialized” doesn’t do it justice. This isn’t just a downsized version of a land-based power plant. It’s engineered from the ground up to survive shock, vibration, salt spray, and the crushing pressures of deep diving—all while staying quiet enough to avoid detection.

The reactor’s job is threefold. First, it drives the submarine’s propeller, pushing the boat through the water at speeds that would drain a battery bank in hours. Second, it generates all the electricity the submarine needs—and modern subs need a lot, between sensors, computers, weapons systems, and climate control. Third, it supports the crew by powering desalination units, air scrubbers, and everything else needed to keep people alive underwater for months.

The science behind it is elegant. Uranium-235 fuel undergoes controlled fission, splitting atoms and releasing heat. That heat gets captured by water circulating through the reactor. The hot water then makes steam, the steam spins turbines, and those turbines do the actual work of moving the submarine and generating electricity. It’s a closed-loop system that can run for years without refueling.

Here’s what makes naval reactors different from civilian ones: they use highly enriched uranium, sometimes up to 97% U-235 concentration. Civilian plants use fuel that’s only 3–5% enriched. The higher enrichment means you can pack way more energy into a smaller core, which is crucial when every cubic meter inside a submarine is fought over by different systems. It also means the reactor can run for decades without needing fresh fuel—some modern designs last the entire 30-year life of the submarine.

The operational impact is profound. With a Nuclear Submarine Reactor, the boat’s endurance isn’t limited by diesel or batteries. It’s limited by food supplies and how long the crew can stand being cooped up underwater. That shift in constraints changes everything tactically and strategically.

Types of Nuclear Submarine Reactor Designs

Over the decades, naval engineers have tried a few different approaches to submarine reactors. Three designs stand out, each with its own trade-offs.

Pressurized Water Reactors (PWRs) are by far the most common. The U.S. Navy uses them. The Royal Navy uses them. The French Navy uses them. There’s a reason for this near-universal adoption: PWRs work, they’re reliable, and they’re relatively safe.

Here’s how they operate. Water in the primary loop flows through the reactor core under intense pressure—about 150 times normal atmospheric pressure. That extreme pressure keeps the water from boiling even at temperatures around 300°C. The superheated water carries the reactor’s heat to steam generators, where it transfers energy to a separate secondary water loop. The secondary water boils, makes steam, and that clean steam drives the turbines.

The beauty of this two-loop system is isolation. The radioactive primary water never touches the steam that actually turns the turbines. If there’s a leak in the secondary system, it’s just water and steam—no radioactive contamination. That separation is a huge safety and operational advantage.

Natural Circulation Reactors take the PWR concept and add a twist. Instead of relying on pumps to move primary coolant, they use temperature differences to create natural convection. Hot water rises, cool water sinks, and the loop circulates on its own.

Why does this matter? Noise. Pumps are one of the loudest components in a reactor plant. Spinning impellers, motors, bearings—they all make sound that can be detected by enemy sonar. A natural circulation reactor can operate at low to moderate power without running pumps at all. For a submarine trying to stay hidden, that’s a massive tactical advantage. Some Russian designs, like the OK-650 and KP-6, can reportedly run at full power using natural circulation alone. American designs like the S5G achieve pump-free operation at reduced power, which is still useful for quiet transits and surveillance work.

Liquid Metal-Cooled Reactors represent the experimental edge of submarine propulsion. The Soviets tried this in their Alfa-class submarines back during the Cold War. Instead of water, these reactors use liquid sodium or other molten metals as coolant.

The advantage is impressive. Molten metal can carry far more heat than water, which means you can build a much more compact, higher-power reactor. For a submarine designer, that’s incredibly tempting—more power in less space means more room for weapons, sensors, and crew.

But the downsides proved severe. Liquid sodium becomes highly radioactive when it circulates through the reactor core. Any leak is catastrophic, not just messy. The pumps have to move heavy, corrosive fluid, which is mechanically challenging. Worst of all, if the reactor cools down too much, the sodium solidifies in the pipes. Imagine trying to restart a reactor with frozen coolant blocking everything—it’s a nightmare scenario.

Most navies decided the risks and complexity weren’t worth the gains. PWRs might be a bit larger, but they’re simpler, safer, and a lot easier to maintain over a 30-year service life.

- PWR baseline: Proven, robust, dual-loop isolation keeps radioactive material contained, excellent shock and survivability characteristics.

- Natural circulation: Pump-free operation at low power dramatically reduces noise, invaluable for stealth-focused missions.

- Liquid metal cooled: High power density potential, but safety, logistics, and lifecycle support challenges have kept it niche.

How Nuclear Submarine Reactor Propulsion Works

Let’s walk through exactly how a Nuclear Submarine Reactor turns nuclear fission into forward motion. It’s a surprisingly elegant process once you break it down.

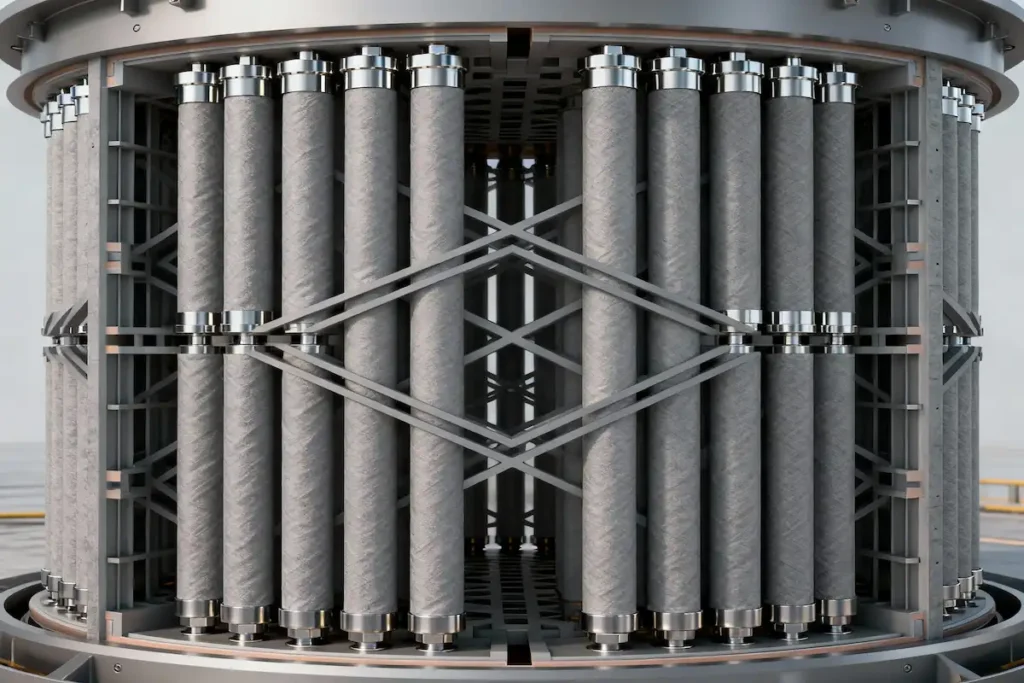

Everything starts in the reactor core. Uranium fuel rods sit in carefully arranged assemblies, and neutrons bounce around splitting U-235 atoms. Each split releases a burst of energy as heat. Control rods made of neutron-absorbing material slide in and out to regulate how fast the reaction proceeds. Slide them in, and the reaction slows. Pull them out, and power increases. It’s all very controllable and precise.

Pressurized water in the primary loop flows through the core, soaking up that heat. This isn’t just warm water—it’s running at about 300°C and under roughly 150 atmospheres of pressure. That pressure is key. It prevents the water from boiling, which keeps heat transfer stable and predictable. If the water boiled, you’d get steam pockets that disrupt coolant flow and reactor control.

The superhot primary water then flows to steam generators. Think of these as big heat exchangers. Primary water runs through thousands of small tubes, and secondary loop water surrounds those tubes. The secondary water is at much lower pressure, so when it touches the hot tubes, it instantly flashes to steam.

This is the critical interface. The radioactive primary circuit and the clean secondary circuit exchange heat but never mix. It’s a hard barrier that keeps radioactive contamination out of the propulsion system. If there’s a leak in the secondary side, you’re dealing with plain steam and water, not radioactive coolant.

The high-pressure steam from the generators rushes into the main propulsion turbines. These are connected through reduction gears to the propeller shaft. As the turbines spin, they turn the propeller and push the submarine through the water. Separate turbines generate electricity for everything else onboard—sonar, radar, weapons systems, galley equipment, air conditioning, you name it.

After doing its work, the steam exhausts at low pressure into condensers cooled by seawater. The steam condenses back into water, and pumps send it back to the steam generators to repeat the cycle. It’s a closed loop, continuously recycling the same water over and over.

The whole thing is basically a compact Rankine cycle—the same thermodynamic process used in land-based power plants—but optimized for a constrained, mobile, shock-resistant environment. The result is reliable thrust and power for months on end with zero refueling stops. For an attack submarine, that means unlimited endurance for surveillance, sea denial, and hunter-killer operations. For a ballistic missile submarine, it enables continuous at-sea deterrence patrols that can last three months or more.

Fuel, Enrichment, and Core Life in a Nuclear Submarine Reactor

The fuel in a Nuclear Submarine Reactor is where things get really interesting. This isn’t your typical nuclear fuel—it’s optimized for endurance, compactness, and performance in ways civilian reactors simply don’t require.

Most submarine reactors use highly enriched uranium (HEU), with U-235 concentrations ranging from 20% all the way up to 97%. To put that in perspective, civilian power plants use fuel enriched to only 3–5%. The higher enrichment packs way more fissile material into a smaller volume, which is crucial when space is at an absolute premium.

American and British submarines use weapon-grade HEU at around 93% enrichment. Russian submarines evolved differently, starting with 20% enrichment in early designs and moving to 21–45% in third-generation boats. France took yet another path, transitioning to low-enriched uranium (LEU) below 20% for their newer submarines. Each approach reflects different national priorities around performance, proliferation risk, and industrial capability.

There’s growing international interest in LEU cores to reduce proliferation concerns. The challenge is maintaining performance and endurance with lower enrichment. That requires advances in fuel matrices—using uranium-aluminum or uranium-molybdenum alloys at higher densities, optimizing core geometry, and clever neutron management. It’s technically demanding, but the non-proliferation benefits make it worth pursuing.

The real breakthrough in modern submarine reactors is the life-of-ship core. These are designed to operate for 25 to 40 years without refueling—essentially the entire service life of the submarine. Virginia-class attack submarines use cores rated for 33+ years. Next-generation ballistic missile submarines are targeting 40+ year cores.

Think about what that eliminates. Older submarines had to refuel every 8–15 years. That meant cutting through the pressure hull to access the reactor compartment—a massive, complex, expensive process that took 18 months to two years and cost $600–800 million per boat. The submarine was out of service that entire time. Life-of-ship cores make all that go away. No hull cuts, no refueling downtime, just continuous availability.

How do they achieve such long core life? The secret is burnable poisons. Engineers incorporate neutron-absorbing materials directly into the fuel. Early in the core’s life, when the uranium is fresh and highly reactive, the poisons absorb excess neutrons and keep the reaction controlled. As the uranium gradually depletes over years of operation, the poisons deplete too, releasing their neutron-absorbing capacity. The net effect is that reactor criticality stays roughly constant over decades of burnup. It’s an elegant solution that took years of materials science and neutronics research to perfect.

Cooling, Heat Management, and Safety in Nuclear Submarine Reactor Systems

A Nuclear Submarine Reactor generates tremendous heat—hundreds of megawatts of thermal power in a package that fits inside a submarine hull. Managing all that heat reliably, safely, and quietly is one of the toughest engineering challenges in naval design.

The primary cooling system is built to last decades under brutal conditions. We’re talking high pressure, high temperature, constant vibration, potential shock from depth charges or nearby explosions, and corrosive saltwater environments. The piping, pumps, valves, and heat exchangers have to be incredibly robust. Materials are chosen for radiation resistance, corrosion immunity, and structural toughness.

The secondary loop operates at lower pressure, which makes steam generation more efficient. After the steam does its work turning turbines, it condenses in heat exchangers cooled by seawater drawn from outside the hull. The ocean becomes an infinite heat sink, carrying away waste heat from the power cycle. It’s simple, elegant, and it works in any ocean, any temperature, any depth.

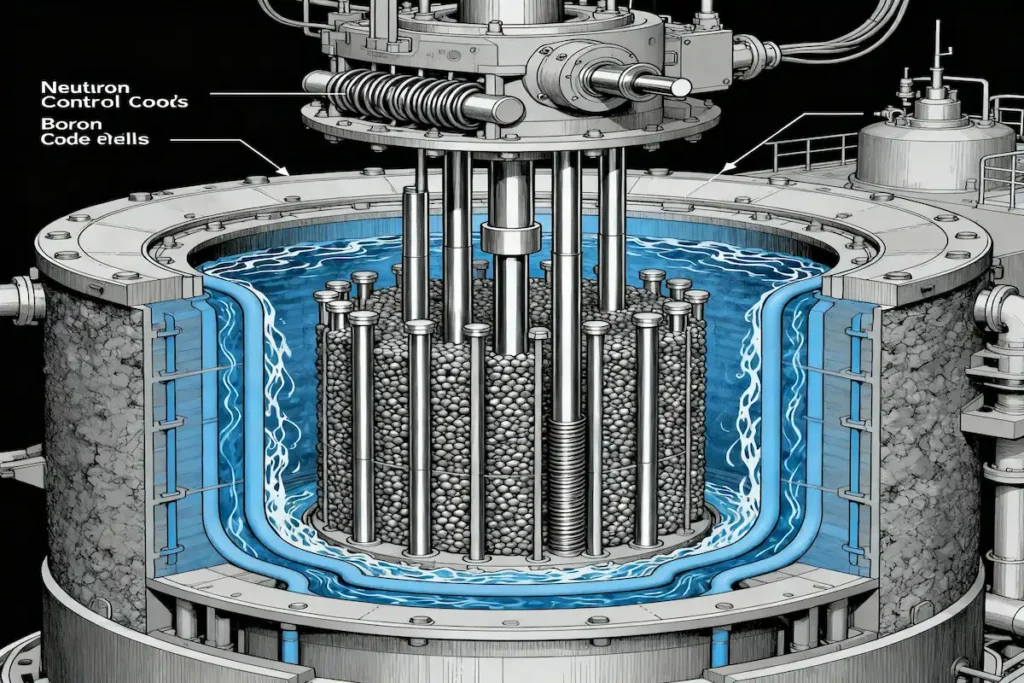

Safety in a submarine reactor is all about layers. The first layer is the control rods, which can scram the reactor—shut down the nuclear reaction—in seconds. The second layer is emergency core cooling systems that can inject water into the core even under high pressure. The third layer is residual heat removal systems that keep cooling the core for days after shutdown, dealing with decay heat from radioactive fission products.

Many modern designs also incorporate passive safety features. Natural circulation is a big one. If pumps fail or lose power, temperature differences alone can keep coolant circulating through the core at low power. That passive heat removal capability adds resilience without requiring active systems, electrical power, or crew intervention.

Interestingly, quieting and safety often go hand in hand. Natural circulation reduces pump noise, which is great for stealth. It also provides passive cooling, which is great for safety. Designs that enable pump-free operation at low to moderate power levels win on both fronts.

Thermal efficiency is intentionally modest in submarine reactors—typically 25–35% compared to 33–37% for large civilian plants. That efficiency penalty comes from design priorities: compactness, shock resistance, quieting, operational flexibility, and rapid load-following. These requirements necessarily reduce thermal efficiency compared to a stationary land plant where space, weight, and noise aren’t major constraints.

But here’s the thing: in naval operations, delivered quiet power across the operational envelope matters far more than peak thermodynamic efficiency. A submarine that can sprint at 30 knots when needed and loiter silently at 5 knots when required is vastly more valuable than one that’s slightly more efficient but less versatile.

(see the generated image above)

Radiation Shielding and Reactor Protection in Nuclear Submarine Reactor Plants

Protecting the crew from radiation while keeping the submarine compact enough to be tactically effective is a fundamental design challenge. The solution is a carefully engineered combination of materials, geometry, and procedures.

Shielding is a composite affair. Steel and water provide bulk protection against both neutrons and gamma rays. Lead is excellent at stopping gamma radiation due to its high density and atomic number—it’s why dentists still drape lead aprons during X-rays. For neutrons, boron-bearing materials like borated polyethylene are the go-to choice. Boron-10 absorbs neutrons extremely well, and wrapping it in a polymer matrix makes it practical to install in tight spaces.

Inside the reactor vessel itself, additional neutron shielding protects the steel pressure vessel from radiation damage. Over years of operation, neutron bombardment can make steel brittle—a phenomenon called embrittlement. Internal shielding reduces that neutron flux, extending vessel life and maintaining structural integrity.

Compartmentalization is the next layer of protection. The reactor compartment is physically isolated from crew spaces, with strict access controls. During operations, that space is essentially a no-go zone. Heavy shielding in the bulkheads—often water-filled voids combined with lead lining—protects adjacent compartments. When maintenance requires access to reactor spaces, the reactor must be fully shut down and cool, and personnel wear dosimeters and follow strict time limits.

Continuous monitoring is the final layer. Area radiation monitors track dose rates throughout the submarine. Airborne contamination detectors sample the air for any signs of radioactive particles. Crew members working near nuclear spaces carry personal dosimeters that record their cumulative exposure. If radiation levels start creeping up, alarms sound and procedures kick in to investigate and correct the problem before anyone’s safety is compromised.

This defense-in-depth approach—multiple independent layers of protection—keeps routine crew exposures well below regulatory limits. Submarine sailors working near the reactor typically receive less radiation exposure over a career than airline pilots flying at high altitude, where cosmic radiation is more intense.

Performance Metrics: Power, Noise, and Efficiency of Nuclear Submarine Reactors

When defense analysts talk about submarine reactor performance, three numbers matter most: how much power it makes, how much noise it produces, and how efficiently it converts heat to useful work.

Thermal power output varies widely depending on the submarine’s mission. British PWR2 reactors produce about 145 megawatts of thermal power, which is enough to drive both Astute-class attack submarines and Vanguard-class ballistic missile submarines. Larger American and Russian boats field reactors in the 200+ megawatt range. Next-generation designs are pushing even higher. India’s BARC is developing 200 MWe submarine reactors that will more than double the output of current Arihant-class systems at 83 MWe. That dramatic power increase enables longer patrols, higher sustained speeds, and much greater electrical capacity for sensors and combat systems.

Acoustic performance can make or break a submarine’s tactical effectiveness. The reactor core itself is silent—there are no moving parts in the fission process. But the supporting systems make noise. Primary coolant pumps are the biggest culprits, with rotating impellers, motor noise, and flow-induced vibrations all contributing to the submarine’s acoustic signature.

This is where natural circulation designs shine. If you can circulate coolant without running pumps, you eliminate a major noise source. Even partial natural circulation at reduced power gives the submarine quiet modes for surveillance, trailing adversary vessels, or evading detection. Russian designs reportedly achieve full-power natural circulation. American designs achieve it at lower power levels. Either way, the tactical advantage is enormous in an environment where sound travels far and detection often means mission failure or worse.

Power conversion efficiency in a submarine reactor runs around 25–35% thermal-to-mechanical. That’s lower than land-based nuclear plants, which hit 33–37%. The efficiency penalty comes from design trade-offs. Submarine reactors prioritize compactness, shock resistance, rapid load changes, and quieting over pure thermal efficiency.

But here’s the reality check: at sea, what matters is operational flexibility. Can the reactor follow load changes quickly as the submarine accelerates or slows? Can it provide both propulsion power and electrical power simultaneously without compromise? Can it operate quietly when stealth is paramount and sprint when speed is needed? Those capabilities matter far more than squeezing out a few more percentage points of thermal efficiency.

Modern submarine reactors are optimized for the mission, not the textbook. That means accepting lower theoretical efficiency in exchange for attributes that actually win fights—endurance, quietness, responsiveness, and survivability.

- Power: Hundreds of megawatts thermal in compact, shock-qualified packages that fit inside a pressure hull.

- Noise: Minimized through pump management, natural circulation modes, isolation mounts, and careful flow path design.

- Efficiency: Intentionally modest (25–35%) to prioritize operational flexibility, stealth, ruggedness, and rapid transients.

(see the generated image above)

Maintenance, Refueling, and Lifecycle of a Nuclear Submarine Reactor

Managing a Nuclear Submarine Reactor over its multi-decade service life is a complex, exacting process that requires specialized facilities, highly trained personnel, and rigorous procedures.

Preventive maintenance is the foundation. Crews and shore-based support teams perform continuous monitoring, routine inspections, and scheduled component replacements. Primary system leak checks catch problems early. Control rod drive testing ensures reliable reactor control. Valve lineups are verified before every operation. Radiation monitoring systems get calibrated regularly. The goal is simple: find and fix small issues before they become big problems.

Data analytics and sensor technology have revolutionized maintenance. Submarines now carry extensive instrumentation that tracks neutron flux, temperature cycling, vibration signatures, and coolant chemistry in real time. Predictive maintenance algorithms analyze trends and flag components approaching their service limits. It’s condition-based maintenance instead of time-based, which is more effective and less disruptive.

For older submarine classes, refueling was a massive undertaking. The process required cutting through the submarine’s pressure hull to access the reactor compartment—literally slicing through several inches of high-strength steel. Spent fuel came out, fresh fuel went in, and major components got inspected or replaced. The whole evolution took 18 months to two years and cost $600–800 million per boat. During that time, the submarine was completely unavailable for operations.

Life-of-ship cores changed everything. Modern submarines like the Virginia class use reactor cores designed to last 33+ years—the entire operational life of the boat. Next-generation ballistic missile submarines are targeting 40+ year cores. No refueling, no hull cuts, no multi-year drydock availabilities. The impact on fleet readiness and lifecycle cost is enormous. More boats are available more of the time, and the total cost of ownership drops substantially.

Even without refueling, end-of-life handling is carefully regulated. When a nuclear submarine retires, the reactor compartment gets cut out as a unit, defueled, and disposed of in approved facilities. The U.S. Navy’s Ship-Submarine Recycling Program manages this systematically, recovering valuable materials, disposing of radioactive components safely, and ensuring environmental compliance. It’s a slow, methodical process, but it’s proven effective over decades of submarine decommissioning.

Throughout the lifecycle, reactor vessel integrity is monitored closely. Neutron bombardment causes gradual embrittlement of the steel pressure vessel. Temperature cycling adds fatigue stress. Corrosion has to be managed. Accelerated testing programs and surveillance specimens help validate that the vessel will remain safe and functional for its entire design life.

Next-Generation Nuclear Submarine Reactor Technologies

The future of submarine reactor technology is being shaped by a few clear trends: more power, better safety, less noise, and longer life between maintenance events.

Advanced reactor designs under development promise significantly higher power output in the same or smaller footprints. India’s BARC is developing 200 MWe submarine reactors that will power the next generation of Arihant-class boats. That’s more than double the current system’s output. The extra power enables longer underwater endurance, supports more capable sensors, and provides margin for future upgrades like directed energy weapons or advanced electronic warfare systems.

Higher power density requires advances across the board—improved fuel designs, enhanced cooling systems, better materials, and tighter integration. It’s not just about making the reactor hotter; it’s about managing that heat safely and quietly in a package that can withstand decades of hard service.

Passive safety systems are a major focus for next-generation designs. These systems use natural phenomena—gravity, convection, thermal expansion—to maintain safety without requiring pumps, valves, or electrical power. If the reactor loses all power, passive systems can still remove heat and prevent core damage. They’re inherently more reliable because there are fewer components to fail.

Natural circulation is one example. Density-driven flow can cool the core even without pumps. Passive residual heat removal systems use heat pipes or natural convection loops to carry decay heat away from the core after shutdown. These features improve both safety and acoustic performance, since fewer active systems mean fewer noise sources.

Low-enriched uranium (LEU) fuel development is a serious effort aimed at reducing proliferation risks. The challenge is maintaining performance with fuel enriched below 20% U-235 instead of the 90%+ enrichment typical of current naval reactors. That requires packing more uranium into the same volume, using advanced fuel forms like uranium-molybdenum alloys, and optimizing core geometry to maintain reactivity and power density.

LEU naval cores would significantly reduce proliferation concerns around submarine programs. It’s technically challenging—you’re fighting physics to get the same performance from lower-enriched fuel—but advances in materials science and neutronics are making it feasible.

Modular reactor concepts aim to reduce construction time and cost through standardization and factory assembly. Instead of building reactors piece by piece in a shipyard, major sections or even complete reactor modules could be manufactured in controlled factory environments with better quality control, then delivered to the shipyard for installation. The approach is borrowed from small modular reactor (SMR) concepts being developed for civilian power generation, adapted for naval applications.

Integrated reactor systems take modularity further by packaging components together that are traditionally separate. French submarines already use integral PWR designs with steam generators built directly into the reactor pressure vessel. Future designs might integrate even more—pumps, pressurizers, control systems—into factory-assembled units. The benefits are compactness, fewer external piping connections (and thus fewer potential leak points), and simpler shipyard integration.

These aren’t pie-in-the-sky concepts. They’re active programs with funding, timelines, and prototype testing. The nations that perfect these technologies first will have a decisive edge in undersea warfare for decades to come.

Environmental, Political, and Security Implications of Nuclear Submarine Reactor Deployment

Nuclear submarine reactors carry implications that extend far beyond their immediate military mission. Environmental concerns, political sensitivities, and strategic dynamics all come into play.

Environmental impact from routine operations is remarkably low. Properly operated submarine reactors are closed systems with essentially zero radioactive releases during normal operations. U.S. Navy data shows total radioactive discharges from all nuclear submarines and support facilities combined amount to less than 0.002 curie annually within 12 miles of shore. To put that in perspective, it’s less radioactivity than naturally occurs in the seawater displaced by a single submarine.

Accident scenarios are more concerning, though the ocean itself provides substantial protection. Water is an excellent radiation shield, and the vast volume of the ocean provides enormous dilution. Historical incidents with sunken nuclear submarines—like the Soviet Komsomolets in 1989—have shown that environmental impacts remain localized due to the ocean’s shielding and dilution capacity. The solid, metallic nature of submarine reactor fuel also helps; it doesn’t dissolve or disperse easily, unlike materials involved in civilian nuclear accidents.

Political sensitivities around submarine reactors center on fuel enrichment and technology transfer. Highly enriched uranium suitable for naval reactors is also potentially weapons material. That creates proliferation concerns when nations develop submarine programs or when established powers share technology with partners.

The AUKUS partnership—Australia, United Kingdom, and United States—has brought these issues to the forefront. Australia’s planned acquisition of nuclear-powered submarines has required new frameworks for sharing sensitive technology while maintaining nonproliferation norms. Efforts to develop LEU naval cores are partly driven by these political concerns, aiming to reduce proliferation risks while preserving military capability.

Strategic implications are profound. Nuclear propulsion fundamentally changes submarine operations and thus naval strategy. Unlimited underwater endurance enables continuous deterrence patrols that are essentially undetectable. Attack submarines can shadow adversary vessels for weeks, gather intelligence in denied areas, or reposition rapidly across theater distances without surfacing.

That persistent, survivable undersea presence shapes everything from nuclear deterrence calculations to regional power balances. Nations with robust nuclear submarine fleets project power differently than those without. The technology is a force multiplier that affects diplomacy, crisis stability, and warfighting capability across the spectrum of conflict.

International maritime law and port access add another dimension. Some nations restrict nuclear-powered vessels from their ports based on environmental or political concerns. New Zealand famously banned nuclear-powered ships in the 1980s, impacting alliance relationships. Japan, despite being a close U.S. ally, has limited nuclear vessel access to certain ports. These restrictions affect deployment patterns, maintenance schedules, and allied cooperation.

Looking ahead, nuclear submarine reactor technology will continue evolving at the intersection of military capability, environmental responsibility, proliferation prevention, and international cooperation. Advanced designs must deliver the operational advantages that undersea forces require while addressing legitimate concerns about safety, security, and global stability. The nations that navigate these multifaceted challenges successfully—balancing power, stealth, safety, and international norms—will maintain decisive advantages in the world’s most demanding and consequential operational domain.